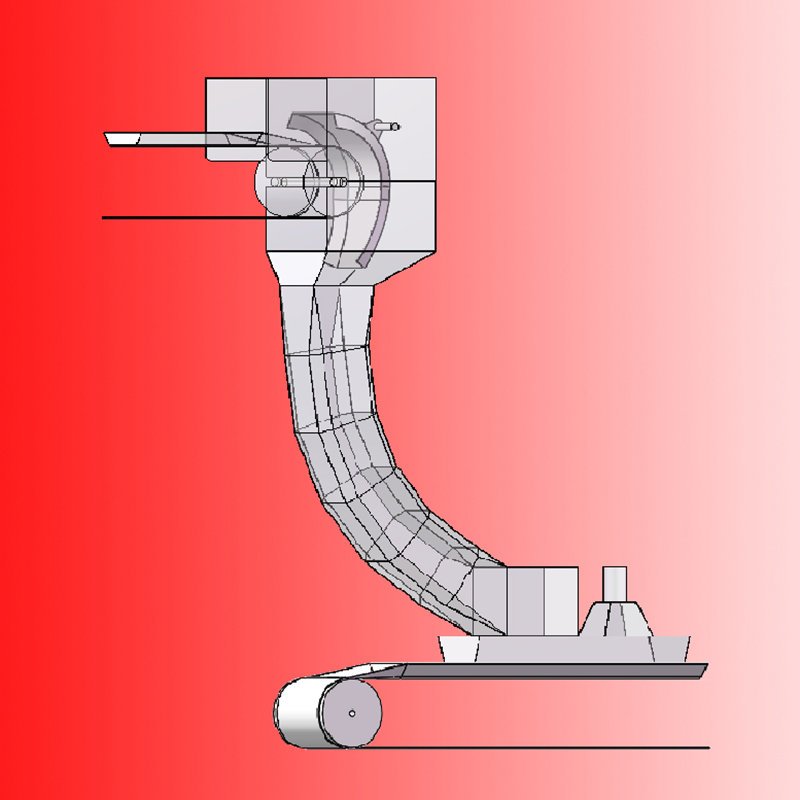

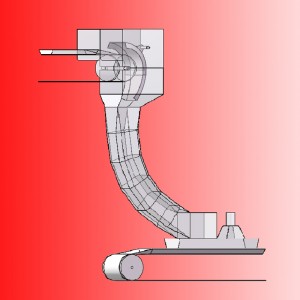

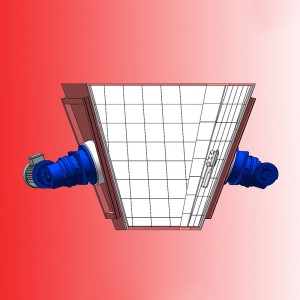

EDEM hyperbolic chute

Product Features

1. Anti-blocking: The speed of the feeding belt makes the kinetic energy of the material flow and the potential energy of the material flow superposed in the drop tube, and the superposed material flow will have the combined energy of the material flow to overcome the friction of the tube wall, so that the material flow can slide down to the receiving tube along the streamlined drop tube through its own energy, thus preventing blockage of the material.

2. Dust suppression: the material flow from the traditional drop tube "explosive" fall into the streamlined drop tube "gathering" orderly fall, control the speed of the falling material flow and the speed of the splicing tape is consistent with the speed of the material flow and the splicing tape is relatively static, eliminating the material flow falling The impact of falling material is eliminated, and most of the dust is suppressed from the source.

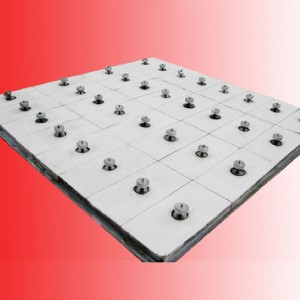

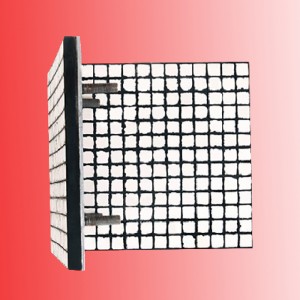

3. Reduce the crushing rate: 3D curve chute system technology based on discrete element method, using three-dimensional software design and three-dimensional modeling technology, with the help of advanced granularity simulation software (EDEM), the behavioral characteristics of the particle system in the bulk material conveying process to carry out a realistic simulation, so as to assist the designers in the design, testing and optimization of the bulk material handling equipment, to ensure that the material can be adhered to the pipe wall, pooled flow, guide the material flow direction, reduce the impact, and reduce the crushing rate.

Scope of Application

Bulk material belt transfer station chute.